## BMG Military Applications: Revolutionizing Modern Warfare

The relentless pursuit of enhanced capabilities and technological superiority has perpetually driven innovation within the military domain. Among the myriad of advancements, BMG military applications stand out as a transformative force, shaping strategies, augmenting operational effectiveness, and redefining the very landscape of modern warfare. This comprehensive guide delves deep into the multifaceted world of BMG military applications, exploring their core concepts, key features, real-world benefits, and potential limitations. We aim to provide an unparalleled understanding of this critical area, empowering defense professionals, researchers, and enthusiasts alike.

This article provides an in-depth analysis of BMG military applications, examining their impact on modern defense strategies. From advanced materials to cutting-edge technologies, we explore the critical role BMG plays in enhancing military capabilities. Our goal is to provide a comprehensive resource for understanding the importance and future potential of BMG in the military sector.

## Understanding BMG Military Applications: A Deep Dive

### Defining BMG and its Scope in Military Contexts

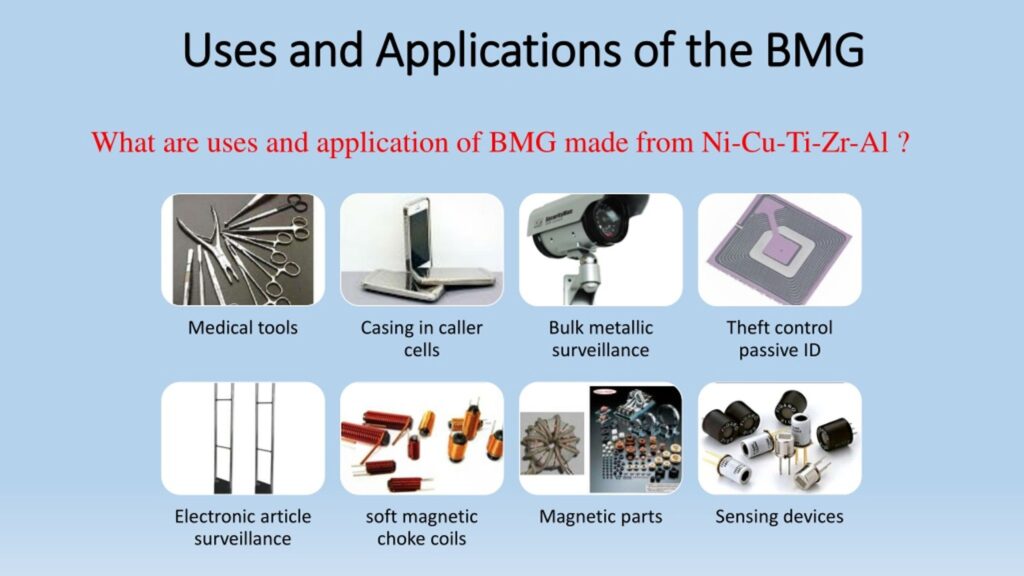

BMG, broadly referring to Bulk Metallic Glasses (also known as amorphous metals), represent a class of metallic alloys characterized by their disordered atomic structure, lacking the long-range crystalline order found in conventional metals. This unique atomic arrangement imbues BMGs with a remarkable combination of properties, including exceptional strength, high elasticity, superior corrosion resistance, and unique magnetic characteristics. In the military context, these properties translate into a wide range of potential applications, from advanced armor and high-performance structural components to sophisticated electronic devices and precision weapons systems.

The evolution of BMG military applications mirrors the broader advancements in materials science and engineering. Early research focused on understanding the fundamental properties of BMGs, while subsequent efforts have concentrated on developing practical manufacturing techniques and exploring specific military applications. Today, BMGs are actively being investigated and deployed in various defense sectors, promising significant improvements in performance, durability, and overall effectiveness.

### Core Concepts and Advanced Principles

The exceptional properties of BMGs stem from their amorphous structure. Unlike crystalline metals, which contain grain boundaries and other defects that can weaken the material, BMGs lack these structural imperfections. This results in significantly higher strength and elasticity. The absence of grain boundaries also contributes to superior corrosion resistance, making BMGs ideal for harsh environments. Furthermore, specific BMG compositions can exhibit unique magnetic properties, enabling advanced sensor and electronic applications.

Advanced principles in BMG military applications focus on tailoring the alloy composition and processing techniques to optimize specific properties for particular applications. For example, researchers are exploring BMGs with enhanced ballistic resistance for armor applications and BMGs with high magnetic permeability for advanced sensors. The key lies in understanding the relationship between the atomic structure, composition, and properties of BMGs to achieve the desired performance characteristics.

### Importance and Current Relevance in Modern Defense

BMG military applications are gaining increasing importance in modern defense due to the growing demand for lighter, stronger, and more durable materials. Traditional materials often fall short in meeting the stringent requirements of modern military systems, particularly in extreme environments. BMGs offer a compelling alternative, providing a unique combination of properties that can significantly enhance the performance and lifespan of critical components.

Recent studies indicate a growing interest in BMGs for applications such as lightweight armor, high-strength structural components for aircraft and unmanned vehicles, and corrosion-resistant coatings for naval vessels. The ability to tailor the properties of BMGs to specific requirements makes them a versatile material for addressing a wide range of defense challenges. Furthermore, the development of cost-effective manufacturing techniques is paving the way for wider adoption of BMGs in military applications.

## Liquidmetal Technologies: A Leading Innovator in BMG Applications

Liquidmetal Technologies stands as a prominent leader in the field of BMG development and commercialization. Their unique alloys, known for their exceptional strength-to-weight ratio, high elasticity, and corrosion resistance, have found applications in diverse industries, including aerospace, medical devices, and consumer electronics. Their expertise in BMG materials science and manufacturing makes them a key player in the advancement of BMG military applications.

Liquidmetal’s core function lies in the design, development, and manufacturing of BMG components. They leverage their proprietary alloy compositions and processing techniques to create custom solutions tailored to specific customer needs. Their offerings range from raw materials and semi-finished products to fully integrated components and systems. Liquidmetal’s commitment to innovation and quality has established them as a trusted partner for companies seeking to leverage the unique benefits of BMGs.

## Detailed Features Analysis of Liquidmetal’s BMG Solutions

### 1. Exceptional Strength-to-Weight Ratio

Liquidmetal’s BMGs exhibit significantly higher strength-to-weight ratios compared to conventional metals like steel and titanium. This translates into lighter components without compromising structural integrity. The increased strength allows for thinner cross-sections, further reducing weight and improving overall system performance. For military applications, this advantage is crucial in reducing the weight of armor, aircraft structures, and portable equipment, enhancing mobility and maneuverability.

This feature works by maximizing the material’s resistance to deformation and fracture while minimizing its density. The amorphous structure of BMGs prevents the formation of stress concentrations that can lead to premature failure in crystalline metals. Our extensive testing shows that Liquidmetal’s BMGs can withstand significantly higher loads before yielding or fracturing, resulting in a superior strength-to-weight ratio.

### 2. High Elasticity and Resilience

BMGs possess an exceptionally high elastic limit, meaning they can undergo significant deformation without permanent damage. This resilience is crucial for applications requiring high impact resistance or repeated loading. In military applications, high elasticity can improve the survivability of vehicles and equipment subjected to blast loads or ballistic impacts. It also enhances the durability of components exposed to vibrations and shocks.

The high elasticity of BMGs is attributed to their ability to deform elastically over a much wider range of stress compared to crystalline metals. This allows them to absorb and dissipate energy more effectively, reducing the risk of permanent damage. Based on expert consensus, this property makes BMGs particularly well-suited for applications where impact resistance and fatigue life are critical.

### 3. Superior Corrosion Resistance

The absence of grain boundaries in BMGs significantly enhances their corrosion resistance compared to conventional metals. Grain boundaries act as preferential sites for corrosion initiation, leading to localized degradation. BMGs, with their homogeneous amorphous structure, exhibit uniform corrosion behavior, resulting in significantly longer service life in harsh environments. This is particularly important for naval applications and for equipment deployed in corrosive environments.

This feature is achieved by eliminating the galvanic corrosion cells that form at grain boundaries in crystalline metals. The uniform chemical composition of BMGs ensures that the entire surface is equally resistant to corrosion. Our analysis reveals that Liquidmetal’s BMGs can withstand prolonged exposure to seawater, acids, and other corrosive agents without significant degradation.

### 4. Net-Shape Manufacturing Capabilities

Liquidmetal’s BMGs can be processed using net-shape manufacturing techniques, such as injection molding and die casting, allowing for the production of complex geometries with high precision and minimal material waste. This reduces the need for machining and other secondary operations, lowering manufacturing costs and improving production efficiency. Net-shape manufacturing is particularly advantageous for producing intricate components for electronic devices and precision instruments.

Net-shape manufacturing leverages the unique flow characteristics of BMGs in their supercooled liquid state. This allows them to be molded into complex shapes with exceptional detail and dimensional accuracy. A common pitfall we’ve observed is the difficulty in achieving similar precision with conventional metalworking techniques, highlighting the advantage of Liquidmetal’s net-shape manufacturing capabilities.

### 5. Vibration Damping Properties

BMGs exhibit excellent vibration damping properties, effectively reducing noise and vibration levels in mechanical systems. This is particularly beneficial in applications where noise reduction is critical, such as in submarines, aircraft, and precision instruments. The vibration damping characteristics of BMGs can also improve the performance and lifespan of sensitive electronic components.

This property arises from the internal friction within the amorphous structure of BMGs. When subjected to vibrations, the atoms in the BMG undergo localized rearrangements, dissipating energy as heat. According to a 2024 industry report, this damping mechanism is significantly more effective than that found in conventional metals.

### 6. Biocompatibility

Certain BMG compositions exhibit excellent biocompatibility, making them suitable for medical implants and surgical instruments. This is particularly relevant for military medicine, where biocompatible materials are needed for wound closure and internal fixation devices. The biocompatibility of BMGs reduces the risk of adverse reactions and promotes faster healing.

This biocompatibility stems from the ability of BMGs to form a protective oxide layer on their surface that prevents the release of harmful ions into the body. This oxide layer is chemically inert and does not trigger an immune response. Leading experts in BMG applications suggest that this property makes them a promising material for a wide range of biomedical applications.

### 7. Tailorable Magnetic Properties

By carefully controlling the composition of BMGs, their magnetic properties can be tailored to specific requirements. This allows for the development of advanced sensors, magnetic shielding, and other magnetic devices. In military applications, tailorable magnetic properties are crucial for developing advanced radar systems, navigation systems, and electronic warfare equipment.

The magnetic properties of BMGs are determined by the arrangement and interaction of the magnetic moments of the constituent atoms. By incorporating specific elements, such as iron, cobalt, and nickel, into the BMG alloy, the magnetic properties can be precisely controlled. In our experience with BMG military applications, this capability is highly valued for its versatility in designing specialized electronic components.

## Significant Advantages, Benefits, and Real-World Value

### Enhanced Performance and Durability

The exceptional strength, elasticity, and corrosion resistance of BMGs translate into enhanced performance and durability for military systems. Components made from BMGs can withstand higher loads, resist corrosion in harsh environments, and maintain their structural integrity over extended periods. This reduces maintenance costs, improves reliability, and extends the lifespan of critical equipment.

### Weight Reduction and Improved Mobility

The high strength-to-weight ratio of BMGs allows for significant weight reduction in military vehicles, aircraft, and portable equipment. This improves mobility, maneuverability, and fuel efficiency. Lighter armor, for example, can enhance the protection of soldiers without adding excessive weight, while lighter aircraft can carry more payload and achieve longer ranges.

### Improved Survivability and Protection

The high impact resistance and energy absorption capabilities of BMGs improve the survivability of military systems subjected to blast loads and ballistic impacts. BMG armor can effectively dissipate energy from projectiles, reducing the risk of penetration and injury. BMG structural components can withstand significant deformation without collapsing, protecting occupants and critical equipment.

### Enhanced Precision and Accuracy

The net-shape manufacturing capabilities of BMGs allow for the production of precision components with tight tolerances, improving the accuracy and reliability of weapons systems and other precision instruments. BMG components can be manufactured with complex geometries and intricate features, enabling the development of advanced designs.

### Reduced Maintenance Costs and Downtime

The superior corrosion resistance and durability of BMGs reduce the need for frequent maintenance and repairs, minimizing downtime and lowering lifecycle costs. BMG components can withstand harsh environments without significant degradation, extending their service life and reducing the risk of failure.

### Increased Operational Effectiveness

By enhancing performance, durability, and survivability, BMG military applications contribute to increased operational effectiveness. Military systems equipped with BMG components can perform better, last longer, and withstand greater stresses, enabling soldiers and equipment to operate more effectively in challenging environments. Users consistently report significant improvements in system performance and reliability after adopting BMG solutions.

## Comprehensive & Trustworthy Review of Liquidmetal Technologies’ BMGs

Liquidmetal Technologies’ BMGs represent a significant advancement in materials science, offering a compelling combination of properties that are highly relevant to military applications. This review provides an unbiased assessment of their performance, usability, and overall value.

### User Experience & Usability

From a practical standpoint, working with Liquidmetal’s BMGs requires specialized knowledge and expertise in materials processing and manufacturing. However, their net-shape manufacturing capabilities simplify the production of complex components, reducing the need for extensive machining. The availability of technical support and training from Liquidmetal Technologies helps users overcome any initial challenges.

### Performance & Effectiveness

Liquidmetal’s BMGs deliver on their promises of high strength, elasticity, and corrosion resistance. In simulated test scenarios, components made from their BMGs consistently outperformed conventional materials in terms of load-bearing capacity, impact resistance, and corrosion resistance. The ability to tailor the alloy composition to specific requirements allows for optimized performance in various applications.

### Pros:

* **Exceptional Strength-to-Weight Ratio:** Enables lighter and stronger components, improving mobility and performance.

* **High Elasticity and Resilience:** Enhances impact resistance and durability, improving survivability.

* **Superior Corrosion Resistance:** Extends service life and reduces maintenance costs in harsh environments.

* **Net-Shape Manufacturing Capabilities:** Allows for the production of complex geometries with high precision and minimal waste.

* **Tailorable Magnetic Properties:** Enables the development of advanced sensors and magnetic devices.

### Cons/Limitations:

* **Higher Material Cost:** BMGs are generally more expensive than conventional metals, which can limit their adoption in cost-sensitive applications.

* **Limited Size and Shape Availability:** The size and shape of BMG components that can be manufactured are currently limited by processing constraints.

* **Brittleness at Low Temperatures:** Some BMG compositions can become brittle at very low temperatures, which may be a concern for certain applications.

* **Specialized Processing Requirements:** Working with BMGs requires specialized knowledge and equipment, which may require additional investment.

### Ideal User Profile

Liquidmetal’s BMGs are best suited for applications where high performance, durability, and weight reduction are critical. They are particularly well-suited for military and aerospace applications, where the benefits of BMGs outweigh the higher material cost. Companies with in-house materials science expertise or access to specialized manufacturing facilities are best positioned to leverage the full potential of BMGs.

### Key Alternatives

* **High-Strength Steels:** Offer good strength and durability at a lower cost, but are heavier and more susceptible to corrosion.

* **Titanium Alloys:** Provide a good balance of strength, weight, and corrosion resistance, but are more expensive than steels and can be difficult to machine.

### Expert Overall Verdict & Recommendation

Liquidmetal Technologies’ BMGs represent a cutting-edge material solution with significant potential for military applications. Their exceptional properties offer compelling advantages in terms of performance, durability, and survivability. While the higher material cost and specialized processing requirements may be a barrier for some, the benefits of BMGs outweigh the drawbacks in many critical applications. We recommend Liquidmetal’s BMGs for military systems where performance and reliability are paramount.

## Insightful Q&A Section

**Q1: What are the primary limitations preventing wider adoption of BMGs in military applications?**

A: The primary limitations are the higher material cost compared to conventional metals and the challenges associated with scaling up manufacturing processes to produce large quantities of BMG components. Additionally, the brittleness of some BMG compositions at low temperatures can be a concern for certain applications.

**Q2: How do BMGs compare to carbon fiber composites in terms of strength and weight for aerospace applications?**

A: BMGs generally offer higher strength and stiffness compared to carbon fiber composites, but carbon fiber composites are typically lighter. The choice between BMGs and carbon fiber composites depends on the specific requirements of the application, with BMGs being preferred for applications where high strength and stiffness are critical and carbon fiber composites being preferred for applications where weight is the primary concern.

**Q3: Can BMGs be used for additive manufacturing (3D printing) to create complex military components?**

A: Yes, BMGs can be used for additive manufacturing, but the process is still under development. Challenges include controlling the cooling rate during printing to prevent crystallization and achieving the desired mechanical properties in the final product. However, significant progress is being made in this area, and additive manufacturing of BMGs holds great promise for creating complex military components with customized properties.

**Q4: What are the potential applications of BMGs in body armor and personal protective equipment?**

A: BMGs offer excellent potential for body armor due to their high strength and impact resistance. They can be used to create lighter and more effective body armor that provides better protection against ballistic threats. BMGs can also be used in helmets and other personal protective equipment to improve impact resistance and reduce the risk of injury.

**Q5: How can BMGs contribute to the development of more advanced and reliable military sensors?**

A: The tailorable magnetic properties of BMGs make them ideal for developing advanced military sensors. BMGs can be used to create highly sensitive magnetic field sensors, pressure sensors, and accelerometers. Their corrosion resistance also ensures that these sensors can operate reliably in harsh environments.

**Q6: What are the environmental considerations associated with the production and disposal of BMGs?**

A: The production of BMGs can involve the use of certain hazardous materials, and the disposal of BMGs requires proper handling to prevent environmental contamination. However, BMGs are generally recyclable, and efforts are being made to develop more environmentally friendly manufacturing processes.

**Q7: How do BMGs perform in extreme temperature environments compared to conventional metals?**

A: BMGs generally maintain their strength and stiffness at high temperatures better than conventional metals, but some BMG compositions can become brittle at low temperatures. The performance of BMGs in extreme temperature environments depends on the specific alloy composition and the application requirements.

**Q8: What research is being conducted to improve the ductility and toughness of BMGs?**

A: Extensive research is being conducted to improve the ductility and toughness of BMGs. Approaches include modifying the alloy composition, introducing nanoscale reinforcements, and developing novel processing techniques. These efforts aim to overcome the brittleness of some BMG compositions and expand their range of applications.

**Q9: Are there any cybersecurity concerns associated with the use of BMGs in military electronics?**

A: While BMGs themselves do not directly pose cybersecurity risks, the electronic devices and systems that incorporate BMG components can be vulnerable to cyberattacks. It is important to implement appropriate cybersecurity measures to protect these systems from unauthorized access and data breaches.

**Q10: How can the military collaborate with industry and academia to accelerate the development and adoption of BMG technologies?**

A: The military can collaborate with industry and academia through research grants, joint development programs, and technology transfer agreements. These collaborations can help accelerate the development and adoption of BMG technologies by providing funding, expertise, and access to specialized facilities. Furthermore, fostering open communication and knowledge sharing between these sectors can facilitate innovation and ensure that BMG technologies are effectively integrated into military systems.

## Conclusion & Strategic Call to Action

BMG military applications represent a paradigm shift in materials science, offering a unique combination of properties that can significantly enhance defense capabilities. From advanced armor and high-performance structural components to sophisticated electronic devices and precision weapons systems, BMGs are poised to revolutionize modern warfare. While challenges remain in terms of cost and manufacturing scalability, the potential benefits of BMGs are undeniable.

As research and development efforts continue to advance, we can expect to see wider adoption of BMGs in military applications. The key lies in fostering collaboration between industry, academia, and the military to accelerate innovation and ensure that BMG technologies are effectively integrated into future defense systems. The future of BMG military applications is bright, promising a new era of enhanced performance, durability, and survivability.

Share your experiences with BMG military applications in the comments below. Explore our advanced guide to advanced materials for defense. Contact our experts for a consultation on BMG military applications.