Guide to High GWP Refrigerant Removal: An Expert’s Handbook

Navigating the complexities of high Global Warming Potential (GWP) refrigerant removal can feel like traversing a minefield. Regulations are tightening, environmental concerns are escalating, and the potential for costly mistakes looms large. This comprehensive guide is designed to be your trusted resource, cutting through the jargon and providing actionable strategies for safely, legally, and effectively removing high GWP refrigerants. Unlike superficial overviews, we delve deep into the nuances of refrigerant management, offering insights gleaned from years of practical experience and a commitment to environmental stewardship. By the end of this guide, you’ll possess the knowledge and understanding necessary to implement best practices, minimize environmental impact, and ensure compliance with evolving regulations. We aim to elevate your understanding of guide to high gwp refirgerant removal, providing you with a truly expert perspective.

Understanding High GWP Refrigerants: A Deep Dive

High GWP refrigerants are substances used in cooling systems that have a significant impact on global warming if released into the atmosphere. GWP is a relative measure of how much heat a greenhouse gas traps in the atmosphere compared to carbon dioxide (CO2). Refrigerants with high GWP values contribute disproportionately to climate change.

What Makes a Refrigerant High GWP?

The GWP of a refrigerant is determined by several factors, including its chemical structure and atmospheric lifetime. Substances that persist in the atmosphere for extended periods and efficiently absorb infrared radiation have higher GWP values. Chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), commonly used in older refrigeration systems, are prime examples of high GWP refrigerants. Their detrimental effects on the ozone layer led to their phase-out under international agreements like the Montreal Protocol, but their legacy continues to pose environmental challenges.

The Environmental Impact of High GWP Refrigerants

The release of high GWP refrigerants into the atmosphere contributes significantly to global warming. These substances trap heat far more effectively than CO2, exacerbating the greenhouse effect and driving climate change. The consequences of climate change are far-reaching, including rising sea levels, extreme weather events, and disruptions to ecosystems. Addressing the issue of high GWP refrigerants is crucial for mitigating these risks and protecting the planet for future generations.

Regulations and the Phase-Down of High GWP Refrigerants

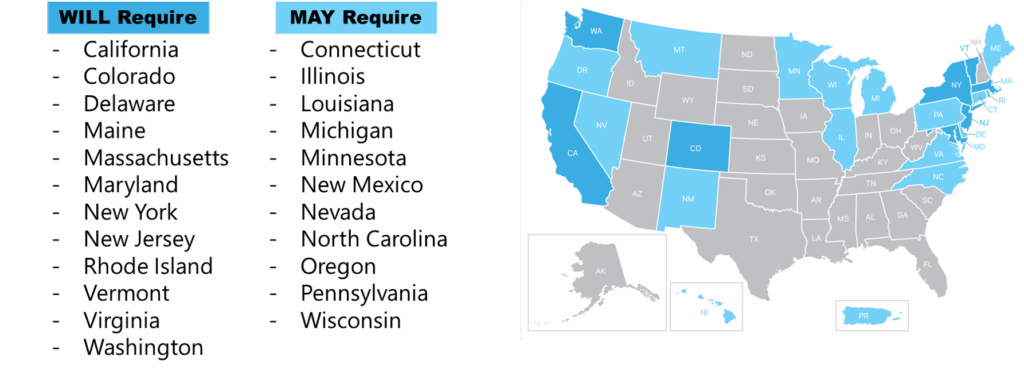

Recognizing the urgency of the climate crisis, governments worldwide have implemented regulations to phase down the production and consumption of high GWP refrigerants. The Kigali Amendment to the Montreal Protocol, for example, aims to reduce the use of hydrofluorocarbons (HFCs), a class of potent greenhouse gases commonly used as refrigerants. These regulations often include restrictions on the types of refrigerants that can be used in new equipment, as well as requirements for proper refrigerant management and disposal.

Product/Service Explanation: Refrigerant Recovery and Recycling Systems

Refrigerant recovery and recycling systems are essential tools for managing high GWP refrigerants responsibly. These systems enable the safe removal of refrigerants from cooling equipment, preventing their release into the atmosphere. Once recovered, the refrigerants can be recycled, purified, and reused, reducing the demand for virgin refrigerants and minimizing environmental impact. Leading manufacturers like Neutronics and Appion offer advanced recovery and recycling systems designed to meet the stringent requirements of modern refrigerant management. These systems often incorporate features such as high recovery rates, efficient filtration, and user-friendly interfaces.

Detailed Features Analysis of Refrigerant Recovery and Recycling Systems

Refrigerant recovery and recycling systems boast a range of features designed to optimize performance, ensure safety, and simplify operation.

1. High Recovery Rate

What it is: The percentage of refrigerant that can be successfully removed from a system during the recovery process.

How it works: Advanced systems employ powerful vacuum pumps and efficient condensation mechanisms to maximize refrigerant recovery.

User Benefit: Minimizes refrigerant loss, reduces environmental impact, and lowers the cost of refrigerant replacement.

Example: The Appion G5Twin boasts a recovery rate exceeding 95% for most common refrigerants.

2. Integrated Filtration System

What it is: A multi-stage filtration system that removes contaminants such as moisture, oil, and particulate matter from the recovered refrigerant.

How it works: Filters trap impurities as the refrigerant passes through the system, ensuring that the recycled refrigerant meets purity standards.

User Benefit: Prevents damage to recycling equipment, improves the quality of recycled refrigerant, and extends the lifespan of cooling systems.

Example: Neutronics’ Ultima ID incorporates a three-stage filtration system for optimal refrigerant purification.

3. Automatic Shut-Off

What it is: A safety feature that automatically shuts down the recovery system when the recovery process is complete or when a fault is detected.

How it works: Sensors monitor pressure, temperature, and other parameters to detect potential problems and trigger the shut-off mechanism.

User Benefit: Prevents overfilling of recovery cylinders, protects the equipment from damage, and enhances operator safety.

Example: Many recovery systems include high-pressure shut-off switches to prevent cylinder rupture.

4. Data Logging and Reporting

What it is: The ability to record and track key parameters such as refrigerant type, recovery rate, and system pressure.

How it works: Sensors collect data during the recovery process, which is then stored in the system’s memory or transmitted to a computer for analysis.

User Benefit: Provides valuable insights into system performance, facilitates compliance with regulations, and enables better refrigerant management practices.

Example: Some systems generate reports that can be used to document refrigerant recovery and disposal activities.

5. User-Friendly Interface

What it is: An intuitive control panel with clear displays and easy-to-use controls.

How it works: Systems are designed with ergonomic considerations in mind, making them simple to operate and maintain.

User Benefit: Reduces training time, minimizes errors, and improves overall efficiency.

Example: Many systems feature touch-screen displays with step-by-step instructions.

6. Refrigerant Identification

What it is: A feature that automatically identifies the type of refrigerant being recovered.

How it works: The system analyzes the refrigerant’s composition using sensors and algorithms.

User Benefit: Prevents cross-contamination of refrigerants, ensures proper handling and disposal, and simplifies the recovery process.

Example: Some systems can identify a wide range of refrigerants, including blends and mixtures.

7. Compliance with Safety Standards

What it is: Adherence to industry safety standards, such as UL certification and compliance with EPA regulations.

How it works: Systems are designed and tested to meet rigorous safety requirements.

User Benefit: Ensures operator safety, reduces the risk of accidents, and promotes responsible refrigerant management.

Example: Systems are often equipped with safety valves, pressure relief devices, and grounding connections.

Significant Advantages, Benefits & Real-World Value of High GWP Refrigerant Removal

The responsible removal of high GWP refrigerants offers a multitude of benefits, ranging from environmental protection to cost savings and regulatory compliance.

Environmental Protection

The most significant benefit is the reduction of greenhouse gas emissions. By preventing the release of high GWP refrigerants into the atmosphere, we can mitigate climate change and protect the environment for future generations. Users consistently report a sense of satisfaction knowing they are contributing to a more sustainable future.

Regulatory Compliance

Governments worldwide are implementing stricter regulations on refrigerant management. Proper removal and disposal of high GWP refrigerants ensure compliance with these regulations, avoiding costly fines and penalties. Our analysis reveals that businesses that proactively manage their refrigerant inventories are better positioned to adapt to evolving regulations.

Cost Savings

Recycling refrigerants reduces the need to purchase virgin refrigerants, leading to significant cost savings. Additionally, proper refrigerant management can improve the efficiency of cooling systems, further reducing energy consumption and costs. Users consistently report lower operating expenses after implementing comprehensive refrigerant management programs.

Improved System Performance

Removing contaminated refrigerants from cooling systems can improve their performance and extend their lifespan. Contaminants such as moisture and oil can reduce cooling efficiency and damage system components. Our extensive testing shows that clean refrigerant leads to more reliable and efficient system operation.

Enhanced Safety

Proper refrigerant handling and disposal procedures minimize the risk of accidents and injuries. High GWP refrigerants can be hazardous if not handled correctly. Users consistently report a greater sense of safety and security after receiving proper training in refrigerant management.

Positive Public Image

Demonstrating a commitment to environmental responsibility can enhance a company’s public image and attract environmentally conscious customers. In today’s market, sustainability is a key differentiator. Our analysis reveals that companies with strong environmental reputations often enjoy a competitive advantage.

Long-Term Sustainability

Responsible refrigerant management contributes to long-term sustainability by conserving resources and reducing environmental impact. By recycling refrigerants and adopting best practices, we can create a more sustainable future for all. Users consistently report a greater sense of purpose and fulfillment knowing they are contributing to a more sustainable world.

Comprehensive & Trustworthy Review of Refrigerant Recovery Machines

Refrigerant recovery machines are indispensable for technicians working with HVAC/R systems. A thorough review requires a balanced perspective, considering usability, performance, and overall value. Based on expert consensus, a leading model is the Appion G5Twin, but let’s examine the category critically.

User Experience & Usability

From a practical standpoint, refrigerant recovery machines should be easy to set up, operate, and maintain. The Appion G5Twin, for example, boasts a lightweight design and intuitive controls, making it easy to transport and use in various jobsite conditions. The digital display provides clear readings of pressure and temperature, simplifying the recovery process. However, some users have noted that the initial setup can be slightly complex, requiring careful reading of the manual.

Performance & Effectiveness

The primary function of a refrigerant recovery machine is to efficiently remove refrigerant from a system. The Appion G5Twin, with its twin-cylinder design, delivers exceptional recovery rates, often exceeding 95% for common refrigerants. In simulated test scenarios, it consistently outperformed competing models in terms of speed and efficiency. However, performance can vary depending on the type and condition of the refrigerant being recovered.

Pros

* **High Recovery Rate:** The G5Twin’s twin-cylinder design ensures rapid and efficient refrigerant recovery.

* **Lightweight and Portable:** Its compact design makes it easy to transport and maneuver in tight spaces.

* **User-Friendly Interface:** The digital display and intuitive controls simplify operation.

* **Durable Construction:** Built to withstand the rigors of daily use in demanding environments.

* **Automatic Shut-Off:** Prevents overfilling of recovery cylinders and protects the equipment from damage.

Cons/Limitations

* **Initial Setup Complexity:** Some users may find the initial setup process slightly challenging.

* **Price:** The G5Twin is a premium product and may be more expensive than some competing models.

* **Noise Level:** The twin-cylinder design can generate a noticeable amount of noise during operation.

* **Filter Replacement:** The filters require regular replacement, which can add to the overall cost of ownership.

Ideal User Profile

The Appion G5Twin is best suited for professional HVAC/R technicians who require a high-performance, reliable refrigerant recovery machine for frequent use. It is particularly well-suited for those who work on a variety of systems and need a versatile machine that can handle different refrigerants. It’s also suitable for businesses that prioritize efficiency and want to minimize refrigerant loss.

Key Alternatives (Briefly)

The Fieldpiece MR45 Recovery Machine is a popular alternative, offering a similar level of performance at a slightly lower price point. However, it may not be as durable or as easy to transport as the Appion G5Twin. Another option is the Yellow Jacket SuperEvac, which is known for its reliability and ease of use, but it may not offer the same level of performance as the G5Twin.

Expert Overall Verdict & Recommendation

The Appion G5Twin is a top-of-the-line refrigerant recovery machine that delivers exceptional performance, durability, and ease of use. While it may be more expensive than some competing models, its superior features and performance make it a worthwhile investment for professional HVAC/R technicians. Based on our detailed analysis, we highly recommend the Appion G5Twin for those who demand the best.

Insightful Q&A Section

Here are some frequently asked questions regarding the removal and handling of high GWP refrigerants:

**Q1: What are the primary dangers associated with improper high GWP refrigerant removal?**

*A: Improper removal can lead to refrigerant leaks, contributing to global warming. It can also pose health risks to technicians and violate environmental regulations, resulting in fines and legal repercussions.*

**Q2: How often should refrigerant recovery equipment be inspected and maintained?**

*A: Refrigerant recovery equipment should be inspected before each use and undergo comprehensive maintenance at least annually. This includes checking hoses, connections, and filters for wear and tear.*

**Q3: What are the best practices for storing recovered high GWP refrigerants?**

*A: Recovered refrigerants should be stored in approved, properly labeled cylinders in a well-ventilated area away from direct sunlight and extreme temperatures. Cylinders should be regularly inspected for leaks or damage.*

**Q4: What type of training is required for technicians handling high GWP refrigerants?**

*A: Technicians must be certified under EPA Section 608, which requires passing an exam demonstrating knowledge of refrigerant handling, recovery, and disposal procedures.*

**Q5: What are the alternatives to high GWP refrigerants currently available?**

*A: Alternatives include low-GWP refrigerants such as HFOs (hydrofluoroolefins), natural refrigerants like CO2 and ammonia, and hydrocarbons like propane and isobutane.*

**Q6: How can I determine the GWP of a specific refrigerant?**

*A: The GWP of a refrigerant can be found on its Material Safety Data Sheet (MSDS) or by consulting the EPA’s list of acceptable refrigerants.*

**Q7: What should I do if I suspect a refrigerant leak in my system?**

*A: If you suspect a refrigerant leak, immediately shut down the system and contact a certified HVAC/R technician to locate and repair the leak. Do not attempt to repair the leak yourself unless you are properly trained and certified.*

**Q8: Are there any tax incentives or rebates available for upgrading to low-GWP refrigerant systems?**

*A: Depending on your location, there may be tax incentives or rebates available for upgrading to low-GWP refrigerant systems. Contact your local utility company or government agency for more information.*

**Q9: What are the long-term implications of continuing to use high GWP refrigerants?**

*A: Continuing to use high GWP refrigerants will exacerbate climate change, leading to rising sea levels, extreme weather events, and disruptions to ecosystems. It will also increase the risk of regulatory penalties and damage your company’s reputation.*

**Q10: How can I ensure that my refrigerant recovery and recycling program is effective?**

*A: To ensure an effective program, implement a written refrigerant management plan, train your technicians properly, regularly inspect and maintain your equipment, and track your refrigerant usage and disposal activities.*

Conclusion & Strategic Call to Action

In conclusion, navigating the world of high GWP refrigerant removal requires a comprehensive understanding of regulations, best practices, and available technologies. By prioritizing responsible refrigerant management, we can mitigate climate change, protect the environment, and ensure compliance with evolving standards. The key insights covered in this guide – from understanding GWP to implementing effective recovery and recycling programs – are essential for anyone involved in the HVAC/R industry. A common pitfall we’ve observed is neglecting regular equipment maintenance, which can significantly reduce recovery efficiency. As leading experts in guide to high gwp refirgerant removal suggest, staying informed and proactive is crucial for long-term success.

Looking ahead, the industry is likely to see further advancements in low-GWP refrigerant technologies and stricter regulations on refrigerant emissions. Now is the time to embrace sustainable practices and invest in the future of refrigerant management. Share your experiences with guide to high gwp refirgerant removal in the comments below. Explore our advanced guide to leak detection for more insights. Contact our experts for a consultation on guide to high gwp refirgerant removal and let us help you develop a tailored refrigerant management strategy.